Mitigates incipient anode-induced corrosion around the boundary of concrete repairs. Mitigates corrosion initiation in new structures.

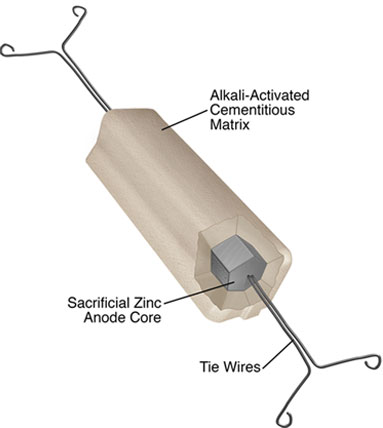

A sacrificial zinc metal embedded within a specially formulated alkaline cementitious mortar. Corr-Stops® Anodes are attached to the reinforcing steel by means of integral wire ties which allow installation in horizontal, vertical and overhead locations.

Corr-Stops® Anodes are installed in accordance with the design engineer’s plans and specifications. In no case should anode spacing exceed 30 inches (750 mm).

| PRODUCT PER PACKAGE | APPROXIMATE SIZE | ZINC WEIGHT | ANODES | PACKAGE WEIGHT |

|---|---|---|---|---|

| Corr-Stops® Anode 40 | 1” x 1 1/4” x 2.5” (25 x 31 x 64mm) |

40 grams | 50 | 15 lbs. (6.8 kg) |

| Corr-Stops® Anode 60 | 1” x 1 1/4” x 5” (25 x 25 x 125mm) |

60 grams | 50 | 20 lbs. (9.1 kg) |

| Corr-Stops® Anode 100 | 1 17/64” x 1 11/32” x 4” (32 x 34 x 100mm) |

100 grams | 40 | 22.5 lbs. (10.2 kg) |

| Corr-Stops® Anode 160 | 1 3/8” x 1 37/64” x 5 1/8” (35 x 40 x 130mm) |

160 grams | 30 | 26.5 lbs. (12 kg) |

The concrete shall be removed from around and behind the steel reinforcement in accordance with good concrete repair practice.

Exposed steel reinforcement shall be cleaned to remove all corrosion products as per the design or industry practice including the back of exposed steel bars. Abrasive blasting is recommended for this process.

Prior to installation of Corr-Stops® Anodes, continuity of the steel reinforcement in the repair area shall be checked. Any discontinuity will require restoration of continuity by traditional means.

Attach Corr-Stops® Anodes immediately following preparation and cleaning of the steel reinforcement.

Install Corr-Stops® Anodes as close as practical to the edge of the broken out repair zone or on a grid pattern as per the engineer’s design.

Corr-Stops® Anodes should be positioned to ensure full encasement within the repair material. Tighten tie wires so no free movement is possible. Electrical continuity between anode wire ties and reinforcement bars shall be tested using a continuity meter.

Concrete cover over Corr-Stops® Anodes should equal the depth of cover to the steel reinforcement to which it is attached but in no case shall be less than 0.75 inches (20 mm).

If reinforcement coatings or bonding agents are used, do not coat the surface of the anode or tie wires.

Repair materials encasing the anode shall be portland cement-based and shall be electrochemically conductive and shall be approved by the design engineer. For more information, refer to ISO12696.

Store in dry conditions in the original unopened packages.

Corr-Stops® Anodes should be handled using gloves and other personal protective equipment as per standard procedures for handling materials containing portland cement.

For professional use only. User shall be responsible to determine suitability of use and assume all risks.

Whilst we endeavor to ensure that any information provided is correct, we cannot accept any liability either directly or indirectly arising from the use of our products as we have no direct or continuous control over where or how our products are applied.